7 Days from Idea to Prototype: How READSUN Optical Redefines Speed, Reliability, and Partnership in Eyewear Manufacturing

- Share

- Issue Time

- Dec 15,2025

Summary

Discover how READSUN Optical transforms eyewear ideas into prototypes in just 7 days. Learn how speed, expertise, and a customer-first attitude help global B2B partners shorten time to market and reduce development risk.

How This Reflects READSUN’s Strength

| Time Concept | Meaning at READSUN |

|---|---|

| 365 Days | Full-year consistency, stable production capacity and service mindset |

| 90 Days | Efficient production line to retail-ready delivery |

| 30 Days | Fast execution from workshop to client operation |

| 7 Days | True competitive edge — rapid prototyping turns ideas into reality |

H1: Speed Is Not a Slogan — It Is a Measurable Capability at READSUN Optical

In the eyewear industry, speed is often promised but rarely delivered with consistency. At READSUN Optical, speed is not a marketing phrase—it is a measurable manufacturing capability built on experience, engineering expertise, and a deeply integrated supply chain.

Our internal philosophy is simple:

Time is not something customers should wait for; it is a distance we help them shorten.

From concept sketches to physical prototypes, from production lines to retail shelves, READSUN controls each stage with clarity and accountability. This is why we confidently state:

“Your design is within reach in 7 days.”

H2: Understanding Time Through a Manufacturer’s Perspective

Many suppliers measure time as a fixed delay. At READSUN, we define time as structured stages that can be optimized, compressed, and controlled.

H2.1: 365 Days — Consistency, Not Seasonal Commitment

365 days represent READSUN’s year-round manufacturing stability.

Our production planning, raw material sourcing, and engineering teams operate continuously, ensuring consistent quality and predictable delivery regardless of seasonality or order size.

For B2B partners, this means reliability—not uncertainty.

H3: 90 Days — From Production Line to Retail Readiness

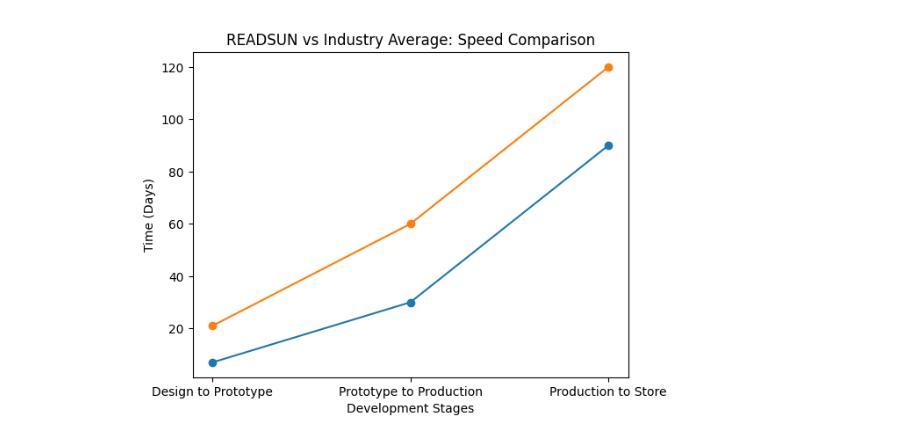

In a typical industry scenario, eyewear production often exceeds 120 days due to fragmented processes and outsourced development.

At READSUN, an integrated production workflow enables most projects to move from mass production to retail-ready delivery within 90 days, significantly reducing time-to-market pressure.

This allows our partners to:

-

Capture seasonal demand windows

-

Launch faster than competitors

-

Improve inventory turnover

H4: 30 Days — From Workshop to the Customer’s Office

Execution matters as much as speed.

READSUN’s optimized internal workflow ensures that once production begins, products move efficiently from workshop to customer operations—often within 30 days.

This level of execution reflects not only operational strength, but also respect for our partners’ business timelines.

H5: 7 Days — Where READSUN Truly Differentiates

H5.1: From Drawing to Prototype in Just 7 Days

The most critical stage in eyewear development is prototyping. Delays here often lead to missed opportunities, increased costs, and repeated revisions.

READSUN’s in-house R&D team, experienced technicians, and rapid prototyping systems allow us to turn design drawings into physical prototypes in as little as 7 days.

This capability delivers clear advantages:

-

Faster decision-making

-

Reduced development risk

-

Shorter product validation cycles

-

Greater flexibility for design iteration

For brands, wholesalers, and distributors, this speed translates directly into competitive advantage.

H6: Speed Requires the Right Attitude

Speed without accountability creates risk.

At READSUN, speed is supported by a professional attitude rooted in collaboration, transparency, and technical responsibility.

H6.1: Engineering-Driven Communication

Design discussions are handled by engineers—not just sales teams.

This ensures feasibility feedback, material recommendations, and structure optimization happen early, saving time and cost for our partners.

H6.2: A Partnership Mindset

We treat customer ideas as shared projects, not transactional orders.

Our role is not simply to manufacture—but to help designs succeed in real markets.

H7: Why Speed and Attitude Matter to B2B Buyers

For today’s eyewear brands and distributors, market timing is everything. Faster development cycles mean:

-

Quicker response to trends

-

Lower financial exposure

-

Higher sell-through potential

-

Stronger brand positioning

By compressing development timelines without compromising quality, READSUN helps partners move from concept to commercialization with confidence.

H8: Experience, Expertise, and Trust — The Foundation of READSUN Optical

READSUN’s speed is built on:

-

Experience: Years of eyewear manufacturing across global markets

-

Expertise: Skilled engineers, structured processes, and material knowledge

-

Authority: Proven OEM/ODM capabilities for international brands

-

Trust: Transparent timelines, consistent quality, and long-term cooperation

These elements form the core of our commitment to EEAT—not just for search engines, but for real business relationships.

Conclusion: Turning Time into Opportunity

In eyewear manufacturing, the difference between success and delay is often measured in days—not months.

With 7-day prototyping, optimized production cycles, and a partnership-driven mindset, READSUN Optical transforms time from a limitation into an opportunity.

Your idea is not distant.

It is within reach. In 7 days.